Contact us

ALUSTEP® 500 is a sandwich panel with a core in aluminum honeycomb faced with fibreglass impregnated with epoxy resin. The application of ALUSTEP SERIES’ panels permits huge savings as far as weight and thickness of slabs of natural stones, such as marbles and granite and mosaics are concerned. With the reduction of material and weight, material, logistics and installation costs can be significantly reduced.

|

A - SKINS IN BIDIRECTIONAL GLASS FIBRE FABRIC

B - CORE Aluminium honeycomb

|

Thickness starting from 4 mm to 80 mm

* To Aluminium alloy series 3000 belong: Aluminium alloy 3003, Aluminium alloy 3005, Aluminium alloy 3103, Aluminium alloy 3104

** Ø3/8” on request

TECHNICAL FEATURES

Panel’s weight Ø6 56kg/m3 (Ø 1/4”) |

||||||

• Thickness’ tolerance ± 0,3 mm

|

||||||

Total thickness mm |

5 |

10 |

15 |

20 |

25 |

|

SKINS’ thickness mm |

0,4 + 0,4 |

|||||

CORE’S thickness mm |

4,2 |

9,2 |

14,2 |

19,2 |

24,2 |

|

Weight kg/m2 |

3 |

3,3 |

3,7 |

4 |

4,3 |

|

Technical data sheet for standard panels (dimensions, materials and special finishes on request) |

|||||||

TECHNICAL CHARACTERISTICS OF PANEL |

|||||||

thickness of the panel mm |

from 5 to 100 |

||||||

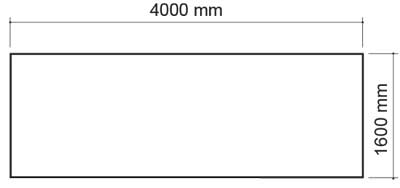

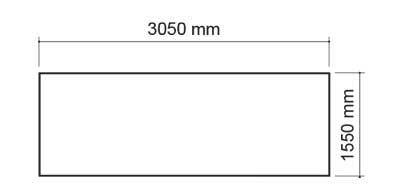

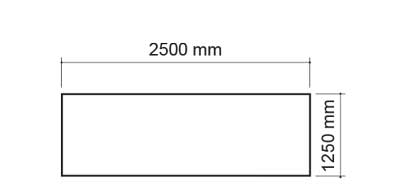

panel size mm |

standard 1250 x 2500 / 1500 x 3050

|

||||||

thickness’ tolerance mm |

± 0,5 |

||||||

dimension’s tolerance mm |

± 30 |

||||||

skins’ thickness mm |

0,4 |

||||||

glass fibre skin |

Glass fibre Plain 500 gr/m² 600 tex |

||||||

Impregnation |

Epoxy resin |

||||||

honeycomb alluminium alloy |

3000 series / 5000 series |

||||||

thickness of honeycomb foil μm |

50 and 70 |

||||||

diameter of honeycomb Ø = mm |

from 3 to 19 |

||||||

honeycomb density Kg/m³ |

from 20 to 163 |

||||||

adhesive for aluminum honeycomb |

Epoxy Resin |

||||||

PANEL PHYSICAL AND MECHANICAL PERFORMANCES |

|||||||

type panel (some examples) mm |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

panel weight ‡ Kg/m2 |

2,5±0,2 |

2,7±0,2 |

3,0±0,2 |

3,3±0,2 |

3,6±0,2 |

3,8±0,2 |

4,1±0,2 |

compressive stabilised strength MPa ** ‡ ASTM C 365-365 M Mpa |

2,9 ± 0,3 |

||||||

maximum load ** ‡ ASTM C 393 † N |

180±20 |

400±40 |

600±60 |

800±80 |

1.000±100 |

1.200±100 |

1.400±100 |

deflection at maximum load ‡ ASTM C 393 † mm |

55±6 |

28±3 |

18±2 |

13±1 |

11±1 |

9±1 |

8±1 |

skins E Elastic Modulus ** Mpa |

28.000±1.000 |

||||||

moment of inertia I ** mm4/m |

4.000 |

18.400 |

40.000 |

76.000 |

120.000 |

174.000 |

240.000 |

middle resistance to peeling ** ‡ ASTM D1781-98 (2012) |

> 500 N/76 mm or >60 Nmm/mm |

||||||

oad distributed on a 1000 x 1000 x 20mm supported on 2 sides kg |

300 |

||||||

Marble/Panel Bonding Test according to ASTM D 4501 |

suitable bonding, the substrate (stone) breaks down |

||||||

deflection recorded on 1000 x 1000 x 20mm panels supported on 2 sides under 300 kg weight distributed on the whole panel surface mm |

18 |

||||||

maximum service temperature ** °C |

- 40 / + 70; on request + 85 |

||||||

thermal expansion coefficient ** °C-1 |

1,5 * 10-5 / 1,5 mm for ΔT 100 °C for 1 meter length |

||||||

* Tested by Certificating Institute

** Tested by Internal Laboratory

*** Approximate value

† Sample dimension with 4 support points (L, W) 540x540

‡ All values refer to a panel made of aluminum honeycomb with a cell diameter 6 mm 56 kg/m3 and epoxy adhesive

Honeycomb core’s properties |

50 Microns |

|

Type |

Aluminium Alloy 3003/3005/3103/3104 |

|

Ø honeycomb in mm ca. |

6 |

9 |

Ø honeycomb in inches |

1/4" |

3/8" |

Density kg/m3 |

56 - 59 |

39 - 40 |

Compressive stabilised

|

3,0 - 3,5 |

1,4 - 1,95 |

Honeycomb core’s properties |

70 Microns |

|

Type |

Aluminium Alloy 3003/3005/3103/3104 |

|

Ø honeycomb in mm ca. |

6 |

9 |

Ø honeycomb in inches |

1/4" |

3/8" |

Density kg/m3 |

80 - 83 |

54 |

Compressive stabilised

|

4,3 - 4,6 |

2,5 - 2,6 |

STANDARD DIMENSIONS (other dimensions available on request)

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.